What is the Difference Between 3D and Four Quadrant Signal Processing?

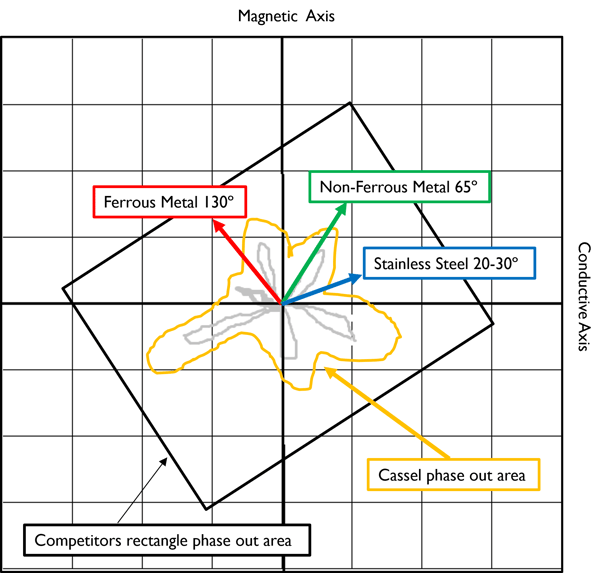

Definition: 3D and four quadrant signal processing refers to how the X and Y (or conductive and magnetic) signals in a metal detector are captured and analyzed. CASSEL Inspection metal detectors use the complete signals from the receive coils as products/metal travel through improving detection probability and sensitivity.

Explanation: All metal detectors generate signals as products/metal passes by each of two receive coils.

- 3D: Refers to the two fundamental signals X and Y (2D) and time (third dimension).

- Four Quadrant Processing: Refers to how both the X and Y signals are captured and analyzed.

CASSEL Inspection metal detectors utilize the full detection signals (in all Four Quadrants, plus and minus), not just peak signals in two quadrants. They also remove product signals by using a unique shape-based teach area where detection thresholds are set depending on the position/signal of the product in the aperture.

Benefits: By utilizing the full signals and applying a shape threshold based on the characteristics of the specific product signals learned at teach time, higher sensitivities can be achieved.

Metal can be detected by either or both receive coils regardless of position in the product as it passes through the aperture. The net result is a higher probability of detection and better sensitivity with a simultaneous reduction in the false reject rate.

Looking for answers to common FAQs about metal detectors? We have you covered! Scroll to the bottom of our helpful information page to learn more.