Dairy Products Reliable inspection to ensure product quality and safety.

Dairy Product Inspection: Protecting Quality from Start to Finish

In the dairy industry, maintaining strict quality standards is critical—not just for product safety, but for preserving consumer trust and brand reputation. Whether it’s milk, cheese, butter, yogurt, sour cream, or cream cheese, dairy manufacturers require reliable foreign material contaminant detection and weight verification.

Most dairy facilities focus on a narrow range of products to keep operations streamlined and efficient. However, contaminants like metal or glass can still enter the production process internally, making inspection systems essential to protect both the product and the brand.

Dairy Product Inspection: Why Do Brands Need It?

In dairy processing, physical contamination risks come primarily from within the facility. Unlike other industries where raw material contamination is common, dairy foreign material contamination is more often the result of mechanical issues—such as metal shavings from mixers, broken bearings, or loose hardware.

With strict sanitation standards, rigorous washdowns, and demanding food safety regulations, dairy producers rely on inspection solutions that can withstand harsh environments and consistently deliver reliable results.

Inspection solutions help dairy brands:

- Maintain the highest food safety standards.

- Prevent costly recalls and brand damage.

- Ensure accurate product weights for regulatory and customer requirements.

- Streamline production efficiency by identifying issues early.

With consumer safety and product integrity at stake, dairy facilities need reliable inspection solutions to protect their products and their reputation.

How is Metal Detection Used in the Dairy Industry?

Metal detection is the most widely used inspection technology in dairy manufacturing. CASSEL Inspection’s metal detectors are designed to detect even the smallest fragments of metal while withstanding the heavy-duty washdown processes required in dairy facilities.

Key advantages of CASSEL metal detectors for dairy applications:

- Available in configurations for low-pressure (IP65) or high-pressure (IP69) sanitation environments.

- Industry-leading detection capabilities with maintenance free design

- Focused on delivering hygienic, easy-to-clean designs critical for dairy production.

During Product Production

Metal and glass contaminants typically originate from inside the facility itself, often from machinery wear and tear. Examples include:

- Strips of metal from mixers.

- Shavings from bearings or mechanical components.

- Metal fragments or shavings from machinery.

- Glass shards from broken containers.

- Hardware like nuts or bolts falling into production during vibration or maintenance.

By integrating metal detection early in the production process, dairy manufacturers can catch physical contaminants before they reach final packaging, reducing rework and safeguarding product integrity.

Final Inspection

Metal detection is equally important after production but before shipping. Final inspection ensures that finished, packaged dairy products are free of contaminants and ready for distribution.

CASSEL Inspection’s durable metal detectors thrive in dairy environments that demand high-pressure sanitation and uncompromising performance.

Metal Detectors for the Dairy Industry

CASSEL offers a variety of metal detection solutions specifically suited for dairy production, including:

- Conveyor Metal Detectors: Ideal for inspecting packaged dairy products like blocks of cheese, tubs of sour cream, or bags of shredded cheese.

- Pipeline or Pump Feed Metal Detectors: Designed for inspecting liquid dairy products such as milk, yogurt, butter, and cream flowing through pipelines.

- Gravity-Fed Metal Detectors: Perfect for free-flowing dairy products like shredded cheese as they move into packaging.

Take a closer look at the Shark MultiSense Metal Detector, offering multi-frequency detection for challenging applications and the ability to withstand IP69 washdown standards.

How is X-ray Inspection Used in the Dairy Industry?

While metal detection is more prominent in dairy facilities, X-ray inspection plays a vital role in certain applications—especially where packaging materials or product characteristics make metal detection difficult.

Key points about X-ray use in dairy:

- X-ray inspection is often more effective than other methods at detecting small physical contaminants embedded in dense products like cheese, where high product effect can interfere with detection.

- X-ray machines can detect both metal and glass contaminants, including tiny shards that might otherwise be missed.

- X-ray can be used when dairy products are packaged in cans (e.g., canned cheese spreads) where metal detection isn't feasible.

- X-ray machines can be built to withstand rigorous washdown requirements. In fact, CASSEL offers rugged, washdown-capable options suited for post-production inspection.

Post-Production Inspection

In the dairy industry, X-ray inspection is most commonly deployed after packaging, when products like canned cheeses or sealed cartons are inspected for glass, metal, or other dense foreign materials.

Confirm Dairy Product Packaging

After packaging, X-ray inspection is used in dairy processing to verify that no foreign materials were introduced during final packaging and confirms that products meet safety and quality expectations.

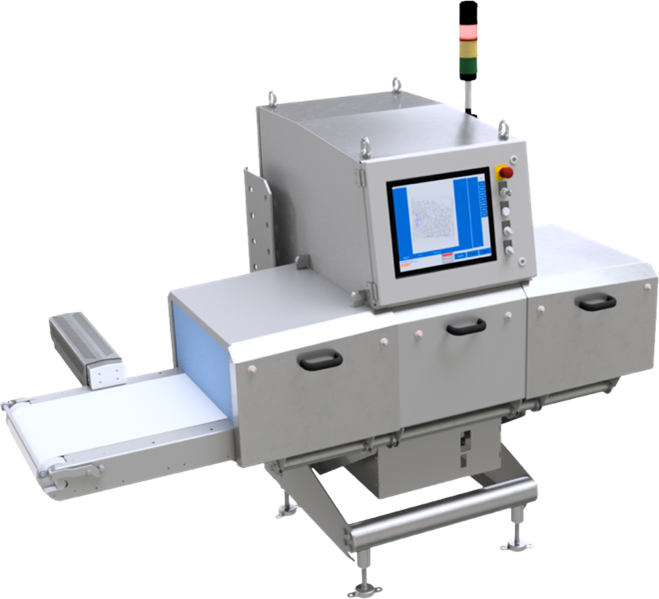

X-ray Inspection Equipment for the Dairy Industry

The choice of X-ray equipment depends on the size and type of packaging—whether inspecting individual dairy products or bulk cases. CASSEL Inspection works with dairy manufacturers and processors to specify the right system for their needs, offering flexibility across small, medium, and large product applications.

CASSEL Inspection’s XD28 and XD38 X-ray inspection systems are built to meet the specific needs of dairy manufacturers, ensuring that every product leaving your facility meets the highest safety and quality standards.

How Are Checkweighers Used in the Dairy Industry?

Checkweighers, like the Teltek C80 Checkweigher, are a critical part of dairy production, helping manufacturers verify that products meet weight tolerances.

Common checkweigher applications in dairy include:

- Packaged Product Verification: For example, ensuring a 1-pound bag of shredded cheese is within the specified +/- weight tolerance to meet requirements.

- Case Weight Verification: Checking that cases (e.g., 12 cups of yogurt) are complete and not missing items.

Accurate checkweighing protects profit margins, ensures regulatory compliance, and minimizes customer complaints related to underweight or incomplete shipments.

Why Choose CASSEL Inspection for Bakery Product Inspection?

CASSEL Inspection brings decades of expertise to the dairy industry, offering rugged, reliable inspection solutions built for the unique demands of dairy production.

Why dairy manufacturers trust CASSEL:

- Hygienic, washdown-ready designs built for harsh environments.

- For providing real-time, non-destructive inspections, which ensure no foreign material contaminants are in the product prior to leaving the manufacturer.

- Exceptional sensitivity for detecting even the smallest physical contaminants.

- Customizable solutions for conveyor, pipeline, and gravity-feed applications.

- Global service and support to minimize downtime, no matter your location.

- Expertise in metal detection, X-ray inspection and checkweighing technologies.

Ready to enhance your dairy product inspection? Connect with a CASSEL Inspection expert today to get a conversation started.