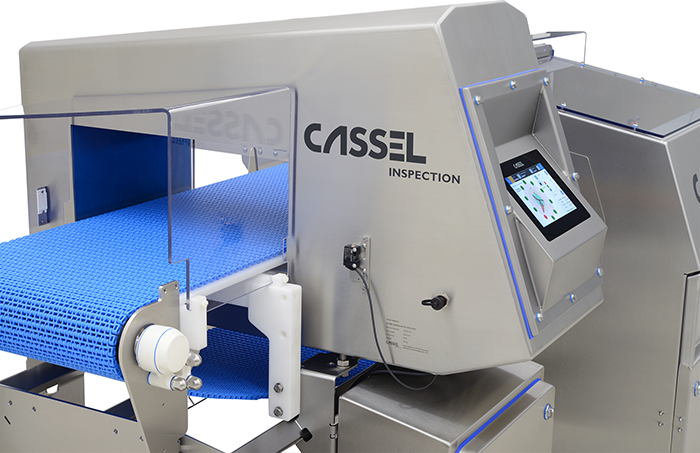

Shark MultiSense Metal Detector

CASSEL Inspection’s Shark MultiSense® metal detector delivers complete protection from metal contaminants. The MultiSense metal detector’s high sensitivity, automated operation, and intelligent signal processing are designed to reduce downtime with automated set-up and auto-learn capabilities, offer an improved probability of detection in even the most challenging applications, and eliminate failed audits and false rejects.

Features

- Improves food safety by detecting up to 50% smaller metal fragments in difficult high product effect application

- Advanced hardware and software features support due diligence to meet a wide range of global food safety standards

- Productivity is enhanced via graphical on-line monitoring with quick adjustment reducing annoying false rejects to near zero

- An all new graphical user interface guides the user along the way making high performance set-up easy to achieve, and ensures the ability to maintain effective, reliable operation 24x7

- Innovative multi frequency technology builds on our legacy of customer focused R&D in metal detection

Function

Multi-dimensional detection and statistical learning capabilities deliver greater accuracy to your food safety systems. With a mechanical and electrical design that is immune to environmental conditions such as wet, humid, high or low-temperatures and electrical interference, you can maximize up-time. Automated operation features increase Overall Equipment Effectiveness (OEE) and operational efficiency.False rejects leading to waste and downtime are no longer a worry due to increased detection sensitivity. Keep your peace-of-mind knowing that the system runs automated audits enabling seamless HACCP certification.

Cleaning is easy with the durable, ergonomic design with an IP69 washdown rating.

Image Gallery

Application

Quality assurance for foods with naturally high product effect which require higher sensitivity such as meats, seafood, frozen goods, chocolate, wet & salty foods, and foods with high mineral content.Specifications

| Model Name/ID | Shark MultiSense Metal Detector |

| Electronics | Two simultaneous frequencies, digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input | 2 analog 0...10 VDC (option: 4-20 mA); Up to 12 freely configurable 24 V DC signals, e.g. for reject confirmation |

| Output | 2 relay CO contacts: “error” and “metal”; Up to 12 freely configurable 24 V DC signals, e.g. for optic/acoustic alarm |

| Inspection Method | High-frequency magnetic field, multi-channel operation, balanced receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel |

| Product Compensation | 250 memory locations, automatic product compensation with Teach Assist |

| Protection Type | IP69 |

| Ambience | -30°C to +40°C / -22°F to +104°F; rel. humidity 20% to 90% non-condensing; >95% rel. humidity (condensing) with closed enclosure |

| Product Temperature | ---- |

| Power Supply | ---- |

| Interface | LAN (for SHARKNET, remote support, diagnostics); USB (Optional) |

| Maintenance | Maintenance-free, self-calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| Conformity | ---- |

Accessories & Extras

- High temperature aperture liners for hot products

- Stainless steel construction for harsh cleaning environments

- SHARKNET connection for automatic documentation according to HACCP, IFS or BRC standard