METAL SHARK® BIG pba

- Specifically designed for the inspection of wood, fiber boards and related upstream products in the production process

- AutoSens technology for automatic adjustment of the sensitivity to the mat height

- Maintenance-free with automatic balance and calibration control

- Durable aluminum design: particularly robust and easy to clean

- Highest sensitivity with 4-quadrant technology

- Auto-calibration and TeachAssistant for intuitive control and easy installation

Features

- Maximum search performance and high reliability in the entire detection space due to 4-quadrant technology

- Simple setup with TeachAssistant

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password protection

- Documentation of all events and metal detection alerts

- Cyclical function monitoring with Performance Validation System (PVS)

- Optional: data transfer to USB interface or connection to the company network via SHARKNET® software

- Resilient to adverse environmental conditions such as high and low temperatures

Function

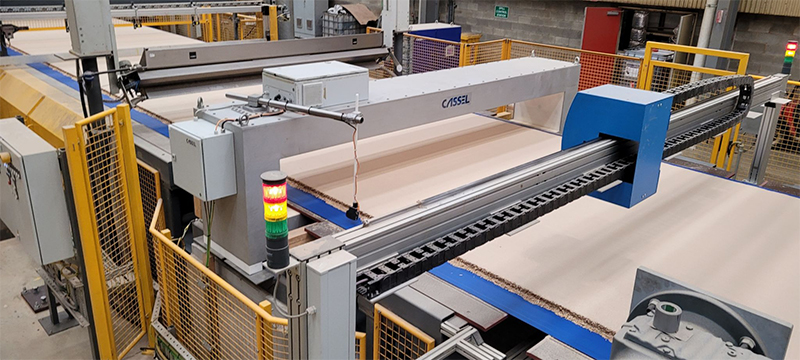

The METAL SHARK® BIG pba with its rectangular tunnel and its fairly low clearance is specifically designed for the monitoring fiber mats, MDF, OSC or chipboard as well as other panel materials.

It is typically installed with a flat belt conveyor.

Due to its 3D detection technology, the METAL SHARK® BIG pba detects magnetic as well as non-magnetic metal contaminants (iron, stainless steel, aluminum, etc.) accurately and reliably even in challenging conditions.

Image Gallery

Delivery Scope

- BIGpba detection unit (sensor)

- Control unit electronic control cabinet with current METAL SHARK® electronics

Application

- Protection of tools and machines from metal objects such as nails, bolts or screws

- Monitoring of particularly large but flat products e.g. paper, cardboard, paper and related upstream products

Specifications

| Model Name/ID | METAL SHARK® BIG pba |

| Electronics | Digital signal processor, digital frequency generation, digital balance control, automatic calibration, digital noise filters, integrated flexible control functions |

| Input | 2 analog 0 ...10 V DC (option: 4-20 mA) 8 freely configurable 24 V DC signals, e.g. for rotary encoders, product identification, pushbutton |

| Output | 2 floating: “error” and “metal” 8 freely configurable 24 V DC signals, e.g. solenoid valve, visual/acoustic alarm |

| Inspection Method | High-frequency magnetic field, multi-channel operation, balanced receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. tombac, brass, aluminium, lead etc.) and stainless steel |

| Product Compensation | 250 memory locations, TeachAssistant |

| Protection Type | IP 65 |

| Ambience | -30°C to +40°C / -22°F to 104°F

UL version: -20°C to +40°C / -4°F to 104°F Optional: -40°C / -40°F or +55°C / 131°F Rel. humidity 20% to 90%, non-condensing > 95% relative humidity (condensing) with control unit closed |

| Product Temperature | Up to 70°C / 158°F |

| Power Supply | Single-phase 110-230 V AC +/- 5%, 20 W typical (60 W max.) |

| Interface | RS232, LAN (optional, for SHARKNET®), USB (optional) |

| Maintenance | Maintenance-free, self-calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| Conformity | CE |

Accessories & Extras

- Xenon flashing light and acoustic signal generator

- AutoSens for automatic adjustment of the sensitivity to the panel height

- SHARKNET® access for perfect documentation and device monitoring from a PC

- Control unit can be mounted separately (e.g. wall mounting)

- ATEX version optionally available

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors to a central computer, providing central storage of all operating data as well as batch and alert documentation and remote control and remote maintenance via a PC |

| Fast Power Drive (FPD) | Significantly improves metal detection capability and reliability in industrial environments that do not meet electromagnetic compatibility standards. Various IP protection classes available, ATEX Zone 22 version optionally available |

| Temperature extension (cold) | Temperature range extended to -40°C / -40°F Resin seals remain elastic at very low temperatures. Special insulation, heated enclosure and other features |

| Temperature extension (hot) | Temperature range extended to +55°C / +131°F Adapted enclosure, additional thermal insulation, heat exchanger and/or active cooling units |

| Flashing light, XENON | Very bright and eye-catching alarm light, 24 V DC, IP 65, RB 10-100 V, 2 W, suitable for mounting on stand or wall mounting |

| Alarm horn | Emits a very loud alarm sound, 24 V DC Suitable for mounting on stand or wall mounting |

| Flashing light + horn on stand | Acoustic and visual alarm on stand, stainless steel, with bright red Xenon flashing light and horn for conveyor mounting |