METAL SHARK FL

- Reliably detects magnetic and non-magnetic metals in fabrics, webs and flat products

- Flat detector surface with rotatable mounting hardware to align with ascending or descending product path

- Easy-to-install under or between conveying lines

- Intuitive control and easy installation with autocalibration and TeachAssistant

- Low maintenance with automatic balance and calibration control

Features

- Best detection sensitivities due to CASSEL’s proprietary signal analysis (4-quadrant technology)

- Memory for up to 250 products

- Easy-to-use with intuitive and multilingual menus

- 4-level password system, automatic log out upon timeout

- Documentation of all events and metal detection alerts

- IFS and HACCP reports available on display at the touch of a button

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET software

- Cyclical function monitoring with Performance Validation System (PVS)

Function

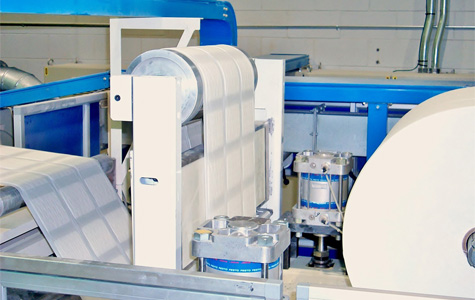

The METAL SHARK FL and FL compact metal detectors are typically used for the inspection of non-wovens, textiles/fabrics and films.

Both detectors are particularly flat and available in widths of 1,000 - 4,000 mm (39" to 157"). The FL compact features a rotatable mount so that it can be adapted to sloping webs.

Due to the high sensitivity of the FL models, even tiny magnetic and non-magnetic metal particles (e.g. iron, aluminum and stainless steel) are detected across the entire width.

Image Gallery

Delivery Scope

- FL or FL compact detection unit (sensor)

- METAL SHARK control unit

Application

- Monitoring of fabric, non-woven or synthetic webs, very shallow products moving on conveyor belts

- Quality assurance for incoming goods, outgoing goods or during ongoing production

- Machine or end user protection, e.g. against needle

Accessories & Extras

- Washable versions for hose cleaning (LPW) or optional high-pressure washdown (HPW)

- SHARKNET connection for automatic documentation including HACCP, IFS or BRC standard

- Separate mounting of the control unit (e.g. wall mounting)

- Signaling devices (visual/acoustic)

- Issue of a Performance Verification Certificate (proof of functionality for audits) by CASSEL service technicians, e.g. during commissioning or maintenance

| SHARKNET | The SHARKNET software connects METAL SHARK metal detectors with a central computer, providing centralized storage of all operating data plus batch and alarm documentation for HACCP and IFS compliance. |

| LPW/HPW | Increase of the IP protection class by adapting the sensor seal, installing additional seals and a double housing for the control electronics |

| Temperature extension cold | Temperature range extended to -40°C (-40° F) Resin seals remain elastic at low temperatures. Special insulation, heated enclosure and other features. |

| Temperature extension hot | Temperature range extended to +55° C, (+131° F) Adapted enclosure, additional thermal insulation, replaceable filter fan, heat exchanger and/or active cooling units. |

| High temperature extension for product | Goods temperature up to +120°C (248° F) max. This option provides IP54 grade enclosure for the sensor. |

| Signalling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes |