METAL SHARK IN Liquid

- Reliably detects metal contaminants in liquid and paste products

- Easy to integrate into common pipeline systems from 1" – 6"

- Stainless steel housing and frame are easy to clean, supplied tube is CIP-capable (Cleaning In Place)

- Highest sensitivity with 4-quadrant technology

- Intuitive control and easy installation through autocalibration and teach-in wizard

Features

- 4-quadrant technology provides maximum search performance with high reliability

- Simple setup with TeachAssistant, preset product types like salty, sweet, wet, dry etc.

- Memory for up to 250 products

- Easy to use with intuitive and multilingual menus

- 4-level password system, automatic log out after time lapse

- Easy to integrate into common pipeline systems

- Documentation of all events and metal messages

- IFS5 and HACCP reports available on the display at the touch of a button

- Optional: Data transfer to USB interface or connection to the company network via SHARKNET software

Function

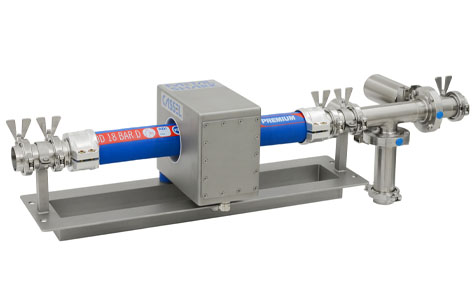

The METAL SHARK IN Liquid is developed for liquid and paste products. With its maintenance-free design and high-quality, hygienic construction, the metal detector is ideal for use in the food industry.

The METAL SHARK IN Liquid can be easily integrated into all common piping systems for pumps, vacuum fillers or even sausage meat filling plants.

Three different valve models, optimally adapted to the respective product, guarantee a safe discharge of metallic contaminants.

Image Gallery

Delivery Scope

- Detection unit (sensor) IN LIQUID incl. mounting frame or mobile stand with 4 rollers

- Controller METAL SHARK® Type IN LIQUID

- Reject unit (arc or butterfly)

- Pressure hose or POM pipe section made of for detection zone incl. matching connectors

Application

- Monitoring of liquid or paste products in pipes between pump and filling station, e.g. soups and sauces, ketchup, mayonnaise, edible oil or processed cheese, creams, toothpaste and much more.

- Even sausage or meat fillings are possible (see also IN Meat)

Specifications

| Model Name/ID | METAL SHARK IN Liquid |

| Type | With automatic rejection (butterfly or arc) |

| Overall Length | 950 to 1630 mm |

| Metal Alarm | Automatic rejection |

| Reject Time | 0.1 – 9.9 sec adjustable |

| Air Pressure | min. 5 bar |

| Delivery Pressure | 16 bar (optional: 40 bar) |

| Frame | Assembly platform frame (optional: mobile stand) |

| Sensitivity | Fe 0.4-0.7, Nfe 0.7-1.0, SS 0.8-1.5 mm |

| Electronics | Digital signal processor, digital frequency generation, digital balance control, automatic calibration, digital noise filters, integrated flexible control functions |

| Input | 2 analog 0…10 VDC (Option: 4-20 mA) ; 8 freely configurable 24 V DC signals, e.g. for reject confirmation |

| Output | 2 floating: “error” and “metal” ; 8 freely configurable 24 V DC signals, e.g. for metal or acoustic alarm |

| Inspection Method | High-frequency magnetic field, multi-channel operation, symmetrical receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel |

| Product Compensation | 250 memory locations, automatic product compemnsation, TeachAssistant |

| Protection Type | IP66 (optionally IP67), Controller IP66 |

| Ambience | Controller: +20°C to +40°C / -4°F to 104°F, option: -40°C / -40°F or +55°C / 131°F,

rel. humidity 20% up to 90% (non-condensing), >95% rel. humidity (condensing) with closed cabinet door Sensor: -30°C to +60°C / -22°F to 140°F Option: Up to +90°C / 194°F |

| Product Temperature | Up to +95°C / 203°F (liquids) or up to +164°C / 327°F (steam) |

| Power Supply | One phase 110-230 V AC +/-5 %, typ. consumption 20 W (max. 60 W) |

| Interface | RS232, provides documentation according to HACCP- and IFS-standard, USB- or ethernet option |

| Maintenance | Maintenance-free, self calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

Accessories & Extras

- Versions for hose cleaning (LPW) or cleaning with high-pressure cleaner (HPW) possible

- SHARKNET® connection for automatic documentation according to HACCP, IFS or BRC standard

- Signalling devices (optical/acoustic)

- Ensuring the functionality by autotest or simple test port for manual insertion of the test ball

Reject Valves

| Butterfly-/Shim valve EX-BF | For liquid and slightly pasty products, very stable, pre-opening on the discharge side prevents recoil into the pipeline, good price/performance ratio, CIP-cleanable, for pressure up to 16 bar |

| Arc valve EX-BOG | For viscous, pasty products or liquid products with solids, CIP-cleanable and free from dead spaces, suitable for cleaning with a pig, for pressure up to 40 bar |

| Piston valve EX-PWC | Suitable for very tough or lumpy products such as sausage meat, internal piston lifts out of the product flow and deflects contaminated product parts, CIP-cleanable, for pressure up to 25 bar |

Hose/Pipe/Connectors

| Pressure Hose | Food safe, applicable up to 6 bar for steam with up to 164°C or 16 bar at 95°C water temperature, in all common sizes from 1″/25 mm to 4″/100 mm |

| Product Pipe | Made of polyoxymethylene (POM) for operating pressure up to 40 bar, in all common sizes from 1″/25 mm to 6″/150 mm |

| Connectors | Milk thread, Triclamp or SMS couplings |

Self-Monitoring

| Testport | Simple version, without valves, with sealing cap (Triclamp) for inserting the test sphere, incl. test bodies |

| Testport Check & Catch | Tube with sealing cap for the insertion of a test body, additional rejection valve to ensure the flow of material during functional testing |

| Autotest | Functional test that does not require opening the product pipelines: Test pieces (FE/NFE/VA) are moved through separate test tubes with compressed air. The control unit indicates which sphere sizes are to be tested. Including pushbutton for FE, NFE and VA testing, pneumatic valve, test piece. |

| Compressed Air Monitoring | Reports an error if the pressure is too low for the functionality of the rejection systems |

| Test Balls | Test balls, diameter 10 mm made of plastic POM, with embedded metal ball made of iron, brass and stainless steel, certified, ball size, metal type and certificate number are embedded in the test ball |

Other Services

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors to a central computer and offers central storage of all operating data as well as batch and alarm documentation for HACCP and IFS conformity. |

| LPW/HPW | Increasing the IP protection type by adapting the sensor seal, installing additional seals and a double housing for the control electronics |

| Signalling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes |

| Performance Verification Certificate | Performance Verification Certificate (proof of functionality for audits) by CASSEL service technicians possible, e.g. during commissioning or maintenance |