There are few issues that impact the global food production and packaging community as universally as food safety. Decades of education and experience have given rise to many systems, standards and codes of practice for ensuring food safety.

While standards may differ in their approach regarding specific geographic regions, industries, and food categories, all are designed to protect brands and end-consumers from physical, chemical and biological contaminants.

Continue reading to learn the most common global food safety standards and codes of practice, and dive into more detail about why food safety is critical to operational efficiency, product safety and the bottom line.

Food Safety Statistics

For USDA-regulated foods—which are meat, poultry, and processed egg products—the top reason for recalls was contamination with foreign materials.

In January 2023, the FDA issued 37 food recalls. Foreign materials were the leading cause of recalls by units with 5.92 million, accounting for 65.5% of the total number of units recalled.

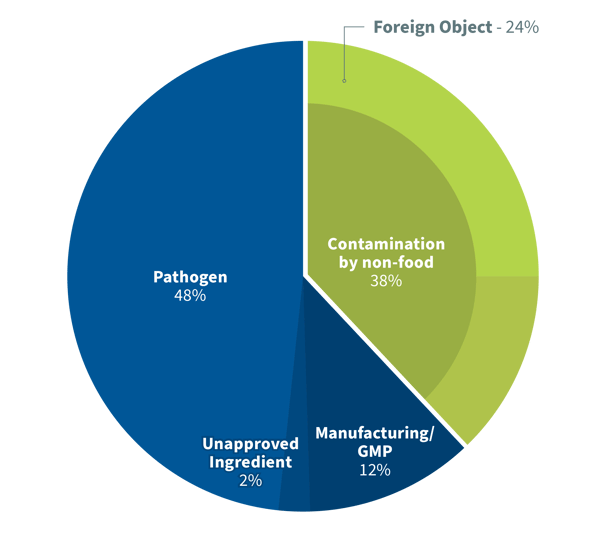

In 2022, the FDA issued more than 400 recalls in the food industry. According to the data shown above, 24 percent of those recalls resulted from foreign object contamination.

What is HACCP? The Gold Standard of Food Safety

Replacing the reactive approaches of the past, HACCP represents a proactive approach to ensuring food safety and security that demonstrates to regulatory agencies and customers that a processor is taking the appropriate precautions to ensure product safety.

Common Standards Relating to Food Safety

Food safety standards range from high-level guides to highly detailed specifications created by standards bodies, government, industry, food producers, and retailers. Requirements can vary by region, food product/package, and producer. The following list illustrates some of the most common standards, with links to more detailed information.

|

Type |

Name |

Description |

|

||

| The BRCGS standard helps companies demonstrate their commitment to product safety, quality, and legal compliance. It also provides a framework for managing product integrity, legality, and quality, which can help companies consistently deliver products and services that meet customer, statutory, and regulatory demands. . |

||

|

M&S COP |

Marks and Spencer Code of Practice (COP) ensures appropriate risk assessments, preventative measures and controls are in place to prevent metal contaminants entering Marks & Spencer products. Suitable detection systems, such as metal detector/X-ray systems must be in place for all Marks & Spencer food products. (confidential, link only available to suppliers) |

Why Food Safety Standards Are Critical for Brands and Consumers

Implementing and enforcing food safety standards is essential for production efficiency and consumer health and safety. Advances in production technology, preservation, and transportation allow manufacturers to produce and distribute massive volumes of products across vast distances. As such, a single food contamination issue can have dramatic impact on consumers and brands.

Food Safety Recalls 2022 and 2023

Here are a few examples of food safety-related recalls from the first quarter of 2023 and the last quarter of 2022 according to Food Safety News:

- Pepsico Inc. is recalling 25,200 cases (12 bottles per case) of Starbucks frappuccino Vanilla drinks because of glass in the product. The products were distributed throughout the U.S.

- Groupe Phoenicia Inc. is recalling Cedar Phoenicia brand Pindjur Vegetable Spread because of pieces of glass found in the product. The products were sold in Alberta, British Columbia, Nova Scotia, Prince Edward Island, Ontario, and Quebec, Canada.

- Swedish cake producer, Almondy, is recalling certain Almondy chocolate cakes with Daim distributed to IKEA stores because a metal object was found in a cake.

- Home Run Inn Frozen Foods is recalling nearly 13,100 pounds of frozen meat pizzas due to potential metal contamination.

- Smithfield Packaged Meats Corp. of Sioux Center, IA, is recalling 185,610 pounds of ready-to-eat (RTE) bacon topping products that may contain extraneous metal.

In addition to threatening public health, food product contamination issues can also be damaging to manufacturers.

According to the Food Marketing Institute and the Grocery Manufacturers Association, the average cost of a food product recall is $10 million, which doesn’t include losses in sales due to brand reputation damage and loss of consumer loyalty.

Metal detectors and X-ray inspection machines are integral elements of any food safety program. It is, however, critical to review your facility’s safety standards to ensure that you’re using systems that will fit the parameters of your production lines and meet your compliance requirements. CASSEL Inspection offers expert technical support to help you select, install, and maintain the best metal detection and X-ray systems for your food safety compliance needs.

Comparing the Capabilities of Metal Detectors and X-ray Inspection Systems

Metal detectors and X-ray inspection systems are the most common CCPs for physical contaminants. They utilize vastly different technologies to find foreign objects though, so selection of each depends on the type of hazards you have, the control limits you set and the place in the line the CCP is installed. X-ray inspection in general has superior detection capability compared to metal detectors, but is also more costly, has a shorter lifespan and cannot be used in extremely harsh factory conditions. If in doubt, work with your product inspection vendor to run tests utilizing both technologies to compare performance. Review overall lifecycle cost too, then you can make an informed decision. Note that some high-quality retailers/customers may demand that X-ray inspection be used for the ultimate brand protection.

Do you want to detect up to 50% smaller metal fragments? The Shark MultiSense is the right choice for your challenging application. See our new technology now.

Detection comparison for metal detectors and X-ray systems

| Contaminant Type | Metal Detector (MD) | X-ray Systems (XR) | Comments |

|

Ferrous Metal |

|

|

Ferrous, Non-Ferrous, Stainless Steel detection varies with MD (i.e. SS most difficult). Product effect for the MD (i.e. water, salt, minerals) and XR (i.e. density, texture) will impact performance too. |

|

Non-Ferrous Metal |

|

|

|

|

Stainless Steel |

|

|

|

|

Aluminium |

|

|

Low density foil impossible for XR. Density similar to glass. Conductivity easier for MD. |

|

Wires |

|

|

MD may miss detection due to orientation. XR depends on length/width. |

|

Glass |

|

|

Depends on the glass composition. Glass size typically > 2.5 X metal. |

|

Rock - Mineral Stone |

|

|

Depends on type and density |

|

Calcified Bone |

|

|

XR only. |

|

Plastic |

|

|

Depends on type and size |

|

Wood, pits, shells, Insects etc. |

|

|

Not conductive for MD, not dense enough for XR |

From foods to pharmaceuticals, any safety standards program can be enhanced with industrial metal detectors and X-ray inspection machines from CASSEL Inspection.

To learn more about the impact of food contamination on brands or how metal detectors and X-ray inspection machines help ensure complete consistent safety and quality in your products, contact our team directly.