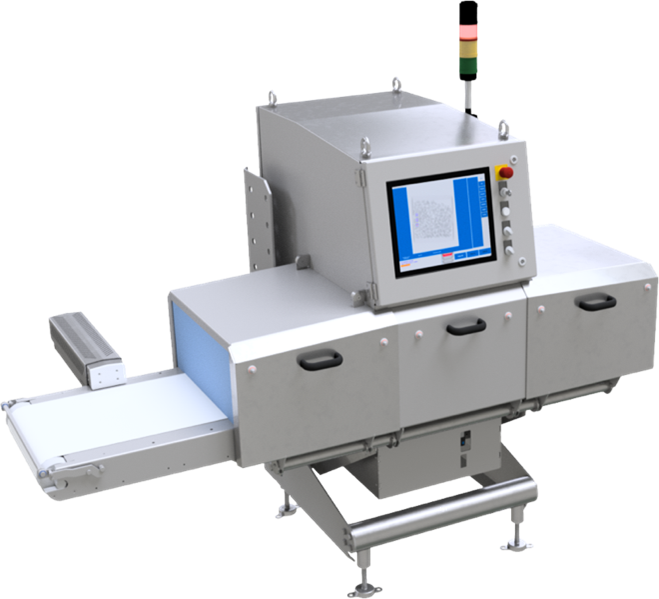

Conveyor Belt X-ray Inspection Machines

CASSEL Inspection’s conveyor belt X-ray inspection machines are designed to offer reliable foreign object detection of packaged and unpackaged products. Our XRAY SHARK® systems provide outstanding physical contamination detection of dense contaminants, including metals, plastics, and stone, and with our side-shot devices, glass contamination in glass containers.

With reliable operation, a user-friendly interface, and low maintenance needs, CASSEL conveyor belt X-ray inspection machines are your best choice for the food, cosmetics, and pharmaceutical industries.

XRAY SHARK XD28 Series

X-ray inspection for packaged products with dimensions W x H: 250×25 mm, 230×50 mm, 200×75 mm, 180×100 mm or 155×125 mm. Suitable for the food industry.

XRAY SHARK XD38

X-ray inspection for packaged products with dimensions W x H: 340x60 mm, 300x100 mm, 250x160 mm or 200x200 mm. Suitable for the food industry.

XRAY SHARK XD47

X-ray inspection for packaged products with dimensions W x H up to 470 x 400 mm. Especially suitable for the food industry.

XRAY SHARK XD68

X-ray inspection for packaged products with dimensions W x H up to 680 x 380 mm oder 320 x 450 mm. Especially suitable for the food industry.

XRAY SHARK XS25 GIG SERIES

XRAY SHARK XS25 GIG SERIES, glass-in-glass inspection in the food or non-food industry. Suitable for containers up to W x H 150 x 250 mm.

XRAY SHARK XS26 GIG

X-ray equipment for finding glass splinters in glass containers in the food or non-food industry. Suitable for glass containers up to W x H 150 x 265 mm.

XRAY SHARK XD BOARD

X-ray inspection for particularly wide and thin products like felts, webs, paper and boards of all kinds. Up to 5 x-ray beams for perfect inspection.