Metal Detection in the Food Industry

Sanitation and product quality are critical in the food and beverage industry. Despite stringent protocols, metal contamination can occur as products move along processing and packaging lines. Detecting contaminants as early as possible so those products can be culled is essential. In the United States, both the USDA and FDA require manufacturers to meet strict metal inspection standards.

Effective metal detection can save money and, when properly implemented, keeps the manufacturing process moving forward smoothly. Additionally, preventing food and beverage contamination:

- Protects consumers, by ensuring safety and satisfaction.

- Protects brand reputation, by avoiding embarrassing and expensive quality defects and product recalls.

- Protects manufacturing equipment, by helping identify potential problems before they escalate.

Did you know that with Shark® MultiSense™ you can detect up to 50% smaller metal fragments in even the most challenging applications? Get the details here.

Types of Contaminants

Industrial metal detectors can be used with packaged goods, liquids and pastes, raw meat, and other product forms. They are designed to detect only ferrous and non-ferrous metals that are conductive and/or magnetic.

- Ferrous metals contain iron, so they are easiest to detect

- Non-ferrous metals such as aluminum, brass, copper, lead, silver and tin are conductive but not magnetic, so they are somewhat more difficult to detect

- Stainless steel is also detectable, though not as easily due to its poor conductive and magnetic properties

CASSEL Inspection metal detectors are designed to detect contaminants based on your unique requirements.

How it Works

An industrial metal detector uses disturbances in a balanced electromagnetic field to identify the presence of metal contamination. CASSEL Inspection metal detection equipment can find the smallest particles of ferrous metals because these are easiest to detect. It can find slightly larger particles of non-ferrous metals, and yet slightly larger stainless steel contaminants because these are respectively more difficult to detect.

The digital signal processor which analyzes the signals must also be sensitive enough to differentiate between contaminants and the product itself. For example, iron-rich foods such as spinach or fortified cereals and salty or moist foods have their own metallic effects. CASSEL Inspection’s multiphase technology assures superior filtering of these effects to avoid false alerts.

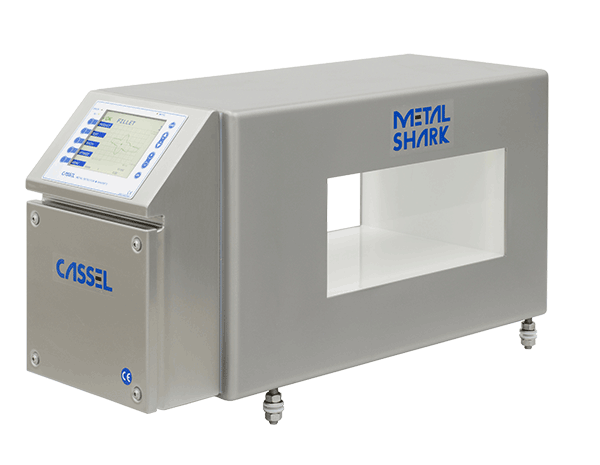

METAL SHARK BD

Metal detector METAL SHARK BD: Metal inspection for packed and loose products on conveyors, perfectly adapted to the food and non-food industry.

METAL SHARK BD-E2 MEAT

Metal detector METAL SHARK BD-E2 meat is specially designed for the inspection of raw meat in E2 standard boxes, very stable easy to clean.

METAL SHARK GF

The GF metal detector for monitoring free falling products (powder, granules, gravel) mainly in the food and non-food industry.

METAL SHARK GF compact

Metal detector GF compact for monitoring free falling products (powder, granules, gravel) mainly in the food and non-food industry.

METAL SHARK IN Liquid

The METAL SHARK IN Liquid metal detector reliably detects metal contaminants in liquid and paste-like products, easy to clean and operate.

METAL SHARK IN MEAT

Metal detector especially for sausage processing with clippers, food safe hose, easy to clean.

METAL SHARK TU

The METAL SHARK TU metal detector for non-separable conveyor belts is particularly easy to install and suitable for all branches of industry.

Conveyor HQ

Metal detector BD and conveyor belt HQ can be integrated as a system solution directly into your production line, ideal for food and non-food industry.

Shark MultiSense Metal Detector

The MultiSense metal detector delivers complete protection from metal contaminants.