X-ray Inspection in the Food Industry

In the United States, the USDA and the FDA both require food and beverage manufacturers to meet strict product quality standards that require diligent inspection.

Metal detectors can identify particles of ferrous and non-ferrous metals as well as stainless steel. However, in the food industry, packaging such as metalized film used for potato chip bags and candy wrappers or prepared food in foil trays can trigger false alerts in metal detectors.

And there are multiple other potential contaminants that are unsuitable for metal detectors. For example, products from farms may contain rocks or glass. X-ray inspection augments metal detectors to assure the discovery of all types of contaminants.

Preventing contamination:

- Protects consumers by ensuring safety and satisfaction.

- Protects brand reputation by avoiding embarrassing and expensive quality defects and product recalls.

- Protects manufacturing equipment by helping identify potential problems before they escalate.

Types of Contaminants

X-ray inspection machine designed for the food and beverage industry can detect:

- Metals

- Glass

- Ceramics

- Plastics

- Stone

- Bone

- PTFE (Polytetrafluoroethylene)

X-ray inspection machines are not able to detect contaminants that can float on water, such as hair, ice, insects, nylon or rubber.

How it Works

Using dual beam technology, CASSEL Inspection X-ray inspection machines for food and beverage can detect any substance that is significantly different in density from the product being inspected. That includes impurities, air bubbles, breaks, or other defects that can compromise the safety or integrity of a product.

Our team of engineers can help you design an inspection solution that integrates seamlessly into your existing processing and packaging lines. You can achieve multi-layer contaminant protection and maximum quality assurance without sacrificing production efficiency.

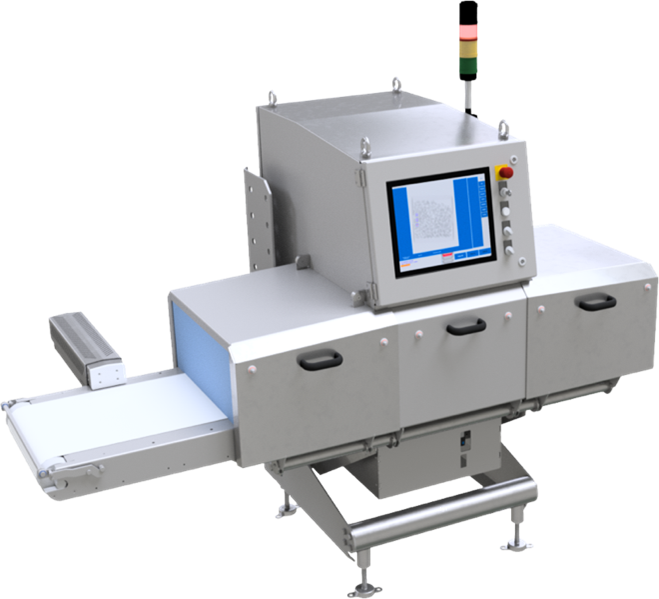

CASSEL Inspection X-ray inspection machines are safe, sensitive, and reliable. With their modular design, our XRAY SHARK® machines have the flexibility to fit into your production environment. They can easily adapt to every unique product you want to inspect, with numerous pre-set options that allow fast and easy product changes.

XRAY SHARK XD28 Series

X-ray inspection for packaged products with dimensions W x H: 250×25 mm, 230×50 mm, 200×75 mm, 180×100 mm or 155×125 mm. Suitable for the food industry.

XRAY SHARK XD38

X-ray inspection for packaged products with dimensions W x H: 340x60 mm, 300x100 mm, 250x160 mm or 200x200 mm. Suitable for the food industry.

XRAY SHARK XD BULK

X-ray inspection for bulk flow products like almonds, nuts or similar materials in the food or non-food industry.

XRAY SHARK XD08-H1-PIPE

X-ray inspection for liquid or pasty products in pipelines. The XD08-H1 detects plastic, stone or glass contaminants, is easy to clean and FDA compliant.

XRAY SHARK XD47

X-ray inspection for packaged products with dimensions W x H up to 470 x 400 mm. Especially suitable for the food industry.

XRAY SHARK XD68

X-ray inspection for packaged products with dimensions W x H up to 680 x 380 mm oder 320 x 450 mm. Especially suitable for the food industry.

XRAY SHARK XS25 GIG SERIES

XRAY SHARK XS25 GIG SERIES, glass-in-glass inspection in the food or non-food industry. Suitable for containers up to W x H 150 x 250 mm.